The Calcium Iodide Manufacturing Plant Project Report provides an in-depth analysis for businesses and investors looking to set up a plant for the production of calcium iodide. As a critical compound in various industries including pharmaceuticals, agriculture, and industrial chemistry, calcium iodide plays a crucial role in iodine supplementation and as a reagent in chemical syntheses. Understanding the technical, financial, and market considerations involved in establishing a manufacturing plant for calcium iodide is key to ensuring a profitable operation.

Request a Free Sample – https://www.procurementresource.com/reports/calcium-iodide-manufacturing-plant-project-report/request-sample

In this article, we will discuss the essential components of the Calcium Iodide Manufacturing Plant Project Report, including the manufacturing process, market analysis, cost structure, procurement resources, and regional insights.

Introduction to Calcium Iodide Manufacturing

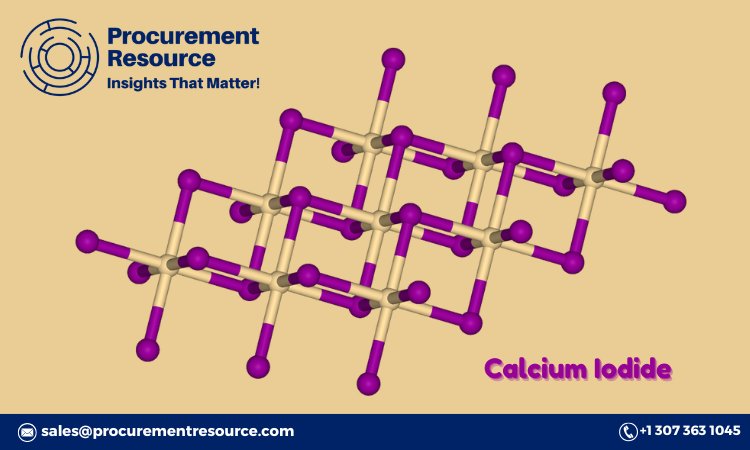

Calcium iodide (CaI₂) is an inorganic compound formed by combining calcium and iodine. It is commonly used in nutritional supplements, pharmaceuticals, and veterinary medicines due to its ability to supplement iodine in animal feed and improve the quality of food and water. Calcium iodide is also used as a catalyst in industrial applications and in the production of other iodides.

Read Full Report With Table Of Contents – https://www.procurementresource.com/reports/calcium-iodide-manufacturing-plant-project-report/toc

The Calcium Iodide Manufacturing Plant Project Report provides an overview of the technical aspects of producing calcium iodide, outlining the necessary processes, equipment, raw materials, and production methods.

Manufacturing Process of Calcium Iodide

The production of calcium iodide typically involves a straightforward chemical synthesis process. The two main raw materials required for calcium iodide manufacturing are calcium carbonate (CaCO₃) or calcium hydroxide (Ca(OH)₂) and iodine (I₂). The general process involves the following steps:

-

Preparation of Calcium Source: The first step in producing calcium iodide is the preparation of calcium hydroxide or calcium carbonate. These materials are typically available in bulk, making them cost-effective and easily accessible.

-

Iodine Addition: In this step, iodine (I₂) is added to the calcium source under controlled conditions. The reaction produces calcium iodide, which is then processed into solid form, typically as white crystalline material.

-

Purification: To ensure the purity of the final product, the calcium iodide is purified through various methods, including filtration and crystallization.

-

Drying and Packaging: The final product is dried to remove any residual moisture and then packaged for shipment or use in various applications.

This simple yet effective process ensures the production of high-quality calcium iodide, which is essential for its intended uses.

Market Analysis for Calcium Iodide

The demand for calcium iodide has seen steady growth, driven by increasing applications in the pharmaceutical and agricultural sectors. As iodine deficiency remains a concern in both human and animal health, the need for iodine supplementation has created a consistent market for calcium iodide. Additionally, the rise of livestock farming and the growing need for high-quality feed and supplements contribute to the demand for calcium iodide.

Regional Market Insights:

-

North America: The North American market for calcium iodide is growing due to the increasing demand in the healthcare and pharmaceutical industries. The region’s established agricultural sector also contributes significantly to the market.

-

Europe: Europe sees substantial demand for calcium iodide in the veterinary and food processing industries. The region is also known for its strong chemical manufacturing base, which supports the production and consumption of calcium iodide.

-

Asia Pacific: The Asia Pacific region, particularly India and China, is witnessing rapid growth in calcium iodide consumption. Rising agricultural practices, livestock farming, and increasing awareness about iodine deficiency in the region drive the demand for the product.

-

Latin America and Middle East: In these regions, calcium iodide is primarily used in the agricultural sector, especially in countries with a growing demand for livestock nutrition and animal health products.

Cost Analysis and Financial Projections

The Calcium Iodide Manufacturing Plant Project Report should include a detailed cost analysis that covers the various stages of production, including raw material procurement, manufacturing, energy costs, labour, packaging, and transportation. Some key cost factors to consider:

-

Raw Materials: The primary raw materials for calcium iodide production, such as calcium carbonate and iodine, are often sourced from local suppliers or global markets. The cost of iodine can fluctuate based on global supply and demand.

-

Energy Costs: The manufacturing process for calcium iodide involves several stages that require significant energy, particularly for drying and crystallization. Energy costs will be a key consideration for the profitability of the plant.

-

Labour: The labour costs associated with running the plant will depend on the location of the plant, local wage rates, and the scale of production. Automation of certain processes may reduce labour costs, but this comes with additional investment in equipment.

-

Logistics and Distribution: Since calcium iodide is primarily distributed in bulk, transportation and logistics costs will be significant. Effective logistics management will ensure timely delivery and cost-efficiency.

-

Packaging: Packaging costs, especially for small-scale deliveries, can add to the overall cost structure. A well-designed packaging system can help mitigate this cost.

-

Plant Setup and Equipment: The initial investment in plant setup, machinery, and infrastructure is another critical factor. This investment will depend on the scale of the production and the level of automation required.

By evaluating these costs, a business can determine the potential return on investment and financial viability of the manufacturing plant project.

Market Insights and Regional Trends

The demand for calcium iodide varies across regions, driven by factors such as agricultural trends, industrial growth, and healthcare advancements. Understanding regional price trends, supply and demand imbalances, and the economic climate is crucial for businesses to position themselves strategically in the global market.

Asia Pacific Market: The Asia Pacific region has emerged as a significant player in the calcium iodide market, driven by large-scale livestock farming and increasing government focus on iodine supplementation for both humans and animals. China and India have shown particular growth, supported by rising demand for animal feed additives.

North America and Europe: In North America and Europe, the demand for calcium iodide is driven by pharmaceutical applications, particularly in the production of iodine-based contrast agents for medical imaging. Additionally, veterinary use in livestock farming supports ongoing demand.

Procurement Resource for Calcium Iodide Manufacturing

Effective procurement strategies are essential to maintaining a consistent and cost-effective production of calcium iodide. Identifying reliable suppliers for raw materials, establishing long-term contracts, and leveraging economies of scale can significantly reduce production costs. Additionally, staying updated on global supply chain disruptions and regional price changes will help procurement managers make timely adjustments to sourcing strategies.

A dedicated procurement team can ensure the timely acquisition of high-quality raw materials at competitive prices, minimising risks related to supply shortages or price volatility.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA