Maximizing Efficiency in Injection Molding Processes

Explore strategies to enhance efficiency in injection molding, focusing on cost-effective production and manufacturability.

Injection Molding Efficiency

In the world of manufacturing injection molding is a big deal. Here are ways to increase efficiency, reduce cost and improve manufacturability in injection molding.

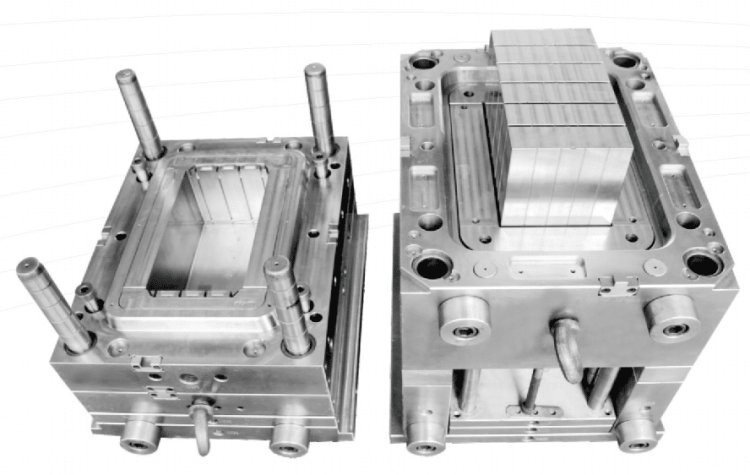

What is Injection Molding

Injection molding is a process of making parts by injecting material into a mold. It’s great for complex shapes with high precision.

Benefits of Injection Molding

-

Cost Efficient: Once the setup is done the cost per part is much lower than other manufacturing methods.

-

High Precision: Injection molding allows for tight tolerances so each part meets spec.

-

Material Options: Many materials to choose from including plastics, metals and composites so design flexibility is high.

Factors that Affect Efficiency in Injection Molding

-

Mold Design: A good mold design can reduce cycle time and improve part quality.

-

Machine Settings: Properly set machines means optimal performance and less waste.

-

Material Selection: Material choice affects flow and cooling times.

Ways to Increase Efficiency

Implement these and you’ll see big gains in injection molding efficiency:

-

Optimize Cycle Times: Analyze and reduce cycle times by tweaking cooling and injection.

-

Automate: Use robotic systems for part handling and assembly to minimize labor and errors.

-

Maintenance: Regular maintenance of machines and molds means no downtime and no costly repairs.

Cost Effective Production

To produce cost effectively:

-

Buy in Bulk: Buy materials in bulk to reduce cost per unit.

-

Energy Efficient: Buy energy efficient machines to reduce operating cost.

-

Lean Manufacturing: Implement lean principles to minimize waste and optimize workflow.

Manufacturability

Manufacturability means designing parts that are easier to produce:

-

Simplified Designs: Reduce complexity in design to make molding and assembly easier.

-

Material Selection: Choose materials that are cost effective and easy to mold.

-

Prototyping: Use rapid prototyping to test design before full production.

Quality Control in Injection Molding

Quality is key in injection molding. Implement good quality control and:

-

Regular Checks: Check at different stages of production to catch defects early.

-

Statistical Process Control: Use data to monitor and control the injection molding process.

-

Employee Training: Train employees on quality standards and best practices regularly.

External Resources

For more information on injection molding:

- China injection molding offers insights into the latest trends and technologies in the industry.

- Plastic mold provides valuable information on mold design and manufacturing processes.

Conclusion

Injection molding efficiency is key to being competitive in manufacturing. Implement mold design, machine settings and cost effective ways and you’ll be golden. Continuous improvement and learning is the key to long term success.

What's Your Reaction?